偶然发现了DataMover这个IP,确实解决了很多问题,一般我们在PL端要读写AXI Slave Port的PS时候,总是很不喜欢写复杂的AXI Full协议.就算实现AXI Lite协议也觉得很累啊.

DataMover就是支持AXIS转AXI接口,配合其他IP可以解决非常多问题,常见情况下PL遇到什么问题.

- PS 端口位宽远比 PL 设计的大得多. - 使用AXI4-Stream Data Width Conveter解决.

- PS 端口的读取性能远比 PL 产生数据速度大得多 - 使用AXI4-Stream Data FIFO解决.

- PS 端口通常使用AXI Full协议,PL实现AXI Full需要重复写的轮子有点多. - 使用AXI DataMover解决.

- PS 端口通常有限,使用AXI Interconnect解决,这是传统方法就不额外说明了.

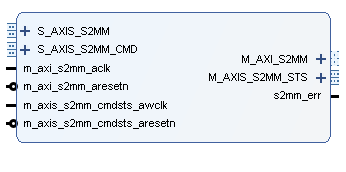

搜索PG022可以找到AXI DataMover的IP文档.这里暂时单纯讨论到PS的写方向,反过来原理也是一样的,总共分为.对于PS侧,PS永远是从机.

- S_AXIS_S2MM - 数据从这里输入,AXIS格式.

- S_AXIS_S2MM_CMD - 如何传输从这里输入,AXIS格式.

- M_AXI_S2MM - 连接PS HP/HPD接口,或者连接AXI Interconnect.

- M_AXIS_S2MM_STS - 传输结果反馈

我们传输数据进去时候,同时要声明我们传输的一些细节,即命令接口.

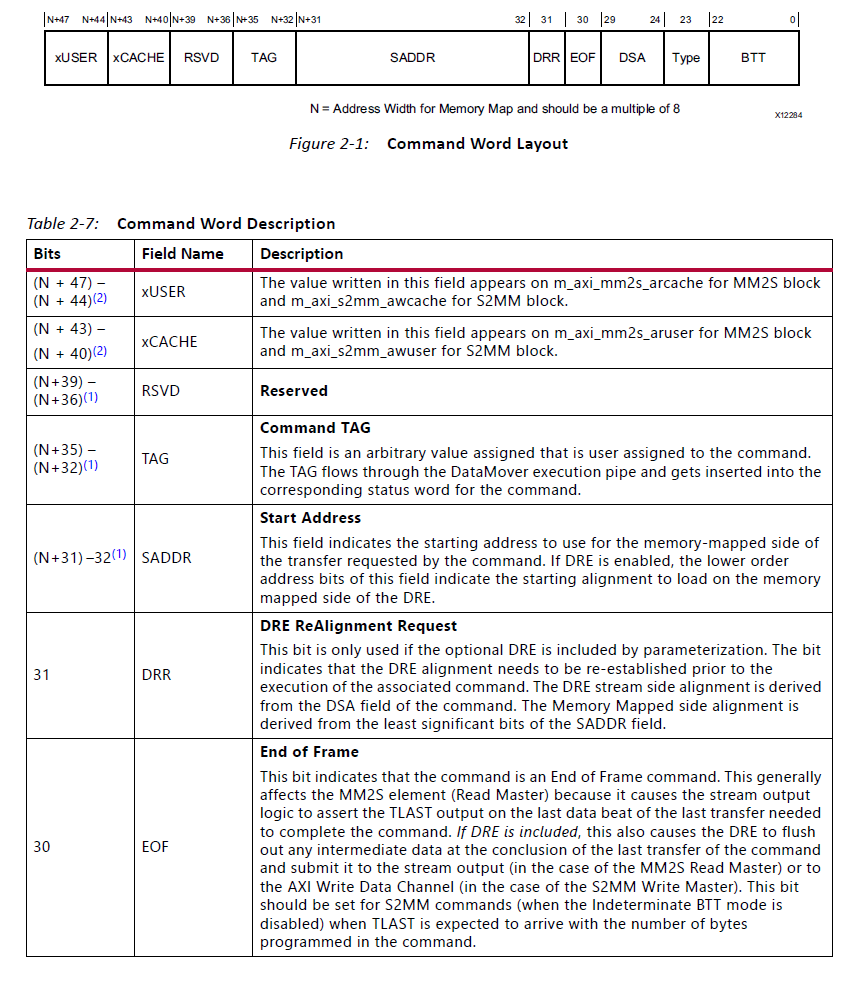

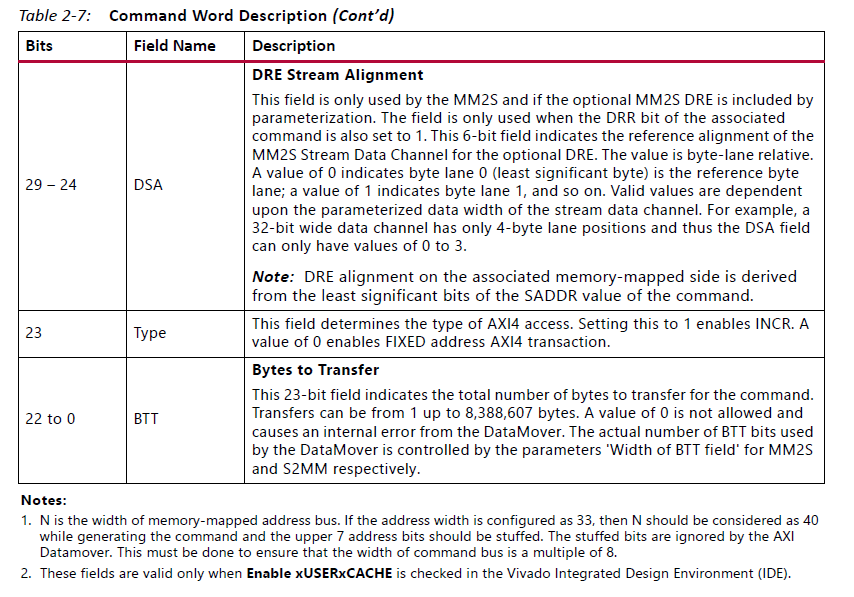

数据映射规则是这样的,假设我们传输的地址是32位.

- BTT[22:0] 要传输的数据量.

- Type[23] 对应突发类型AxBURST.

- DSA[29:24] 当使用数据重新排列引擎(DRE)时,对齐方式的设置,这个可以阅读AXI4-Stream文档了解.

- EOF[30] 如果为1,这一次AXIS传输完要给AXI Slave发送TLAST.

- DRR[31] 前面有讲到.

- SADDR[63:32] 传输的地址,如果是INCR模式就是起始地址了.

- TAG[67:64] 调试用标记

- xCACHE[75:72] 对应传输的AxCACHE

- xUSER[79:76] 对应传输的AxUSER

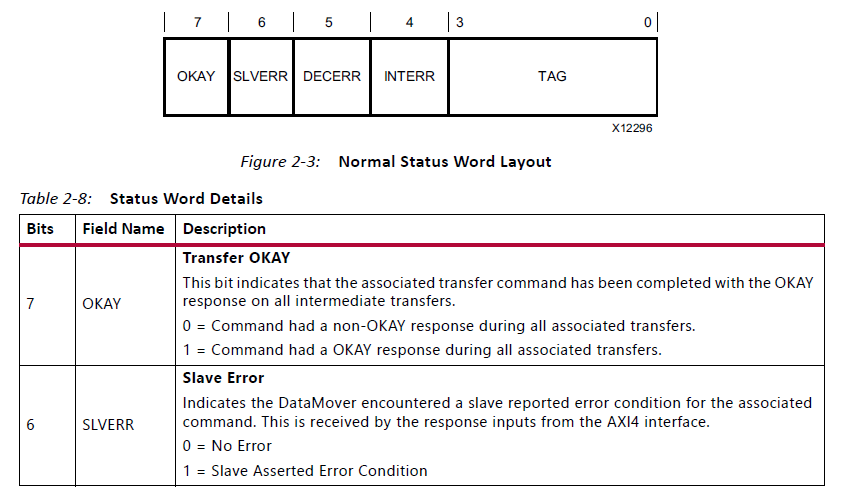

传输结果.

刚才设置的TAG会传递过来,可以用来区分不同的传输.如果最高位是1,那么传输就OK了.

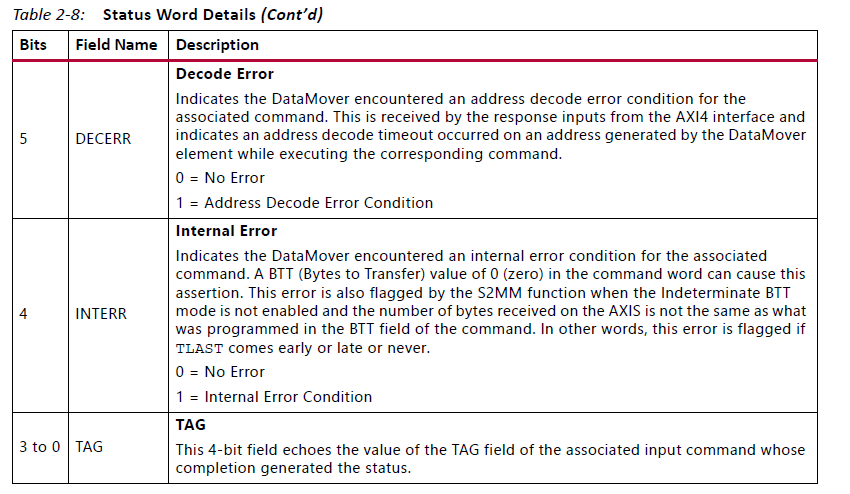

那么整体设计就明朗了.

pl_ddr是按8位数据写的,所以使用位宽转换成64位,由于PL DDR一次提供1字节,而DataMover一次要8字节,明显带宽上有很大差距,所以又连接了一个Data FIFO,要注意STS的READY要拉高,不然第二次传输他就以为是错误了.

PL代码参考.

module pl_ddr(

input wire clk,

(* X_INTERFACE_PARAMETER = "POLARITY ACTIVE_HIGH" *)

input wire rst,

input wire [7:0] i_data,

input wire i_trigger,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS TLAST" *)

output reg m_axis_tlast,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS TKEEP" *)

output reg m_axis_tkeep,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS TDATA" *)

output reg [7:0] m_axis_tdata,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS TREADY" *)

input wire m_axis_tready,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS TVALID" *)

output reg m_axis_tvalid,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS_S2MM_CMD TVALID" *)

output reg m_axis_s2mm_cmd_tvalid,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS_S2MM_CMD TREADY" *)

input wire m_axis_s2mm_cmd_tready,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 M_AXIS_S2MM_CMD TDATA" *)

output reg [71:0] m_axis_s2mm_cmd_tdata,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 S_AXIS_S2MM_STS TVALID" *)

input wire s_axis_s2mm_sts_tvalid,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 S_AXIS_S2MM_STS TREADY" *)

output wire s_axis_s2mm_sts_tready,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 S_AXIS_S2MM_STS TLAST" *)

input wire s_axis_s2mm_sts_tlast,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 S_AXIS_S2MM_STS TKEEP" *)

input wire s_axis_s2mm_sts_tkeep,

(* X_INTERFACE_INFO = "xilinx.com:interface:axis:1.0 S_AXIS_S2MM_STS TDATA" *)

input wire [7:0] s_axis_s2mm_sts_tdata

);

reg [2:0] sync_trigger_ff;

// 信号为高时发生上升沿

wire sync_trigger = !sync_trigger_ff[2] && sync_trigger_ff[1];

reg [15:0] counter;

reg [1:0] state;

assign s_axis_s2mm_sts_tready = 1'b1;

always @ (posedge clk) begin

if(rst) begin

sync_trigger_ff <= 0;

end else begin

sync_trigger_ff <= {sync_trigger_ff[1:0],i_trigger};

end

end

always @ (posedge clk) begin

if(rst) begin

m_axis_tdata <= i_data;

counter <= 0;

state <= 0;

end else begin

case (state)

2'b00: begin

counter <= 0;

m_axis_tdata <= i_data;

if(sync_trigger) begin

state <= 2'b01;

end else begin

state <= 2'b00;

end

end

2'b01: begin

if (counter < 8192) begin

if(m_axis_tready) begin

m_axis_tdata <= m_axis_tdata + 1'b1;

counter <= counter + 1'b1;

end

end else begin

state <= 2'b00;

end

end

endcase

end

end

// TVALID

always @ (posedge clk) begin

if(rst) begin

m_axis_tvalid <= 0;

end else begin

if(state == 2'b01 && counter < 8192) begin

m_axis_tvalid <= 1'b1;

end else begin

m_axis_tvalid <= 1'b0;

end

end

end

// TLAST

always @ (posedge clk) begin

if(rst) begin

m_axis_tkeep <= 0;

end else begin

if(state == 2'b01) begin

m_axis_tkeep <= 4'b1111;

end else begin

m_axis_tkeep <= 4'b0000;

end

end

end

// TKEEP

always @ (posedge clk) begin

if(rst) begin

m_axis_tkeep <= 0;

end else begin

if(state == 2'b01) begin

m_axis_tkeep <= 4'b1111;

end else begin

m_axis_tkeep <= 4'b0000;

end

end

end

// 锁存器可以暂时锁存CMD直到TREADY

always @ (posedge clk) begin

if(rst) begin

m_axis_s2mm_cmd_tvalid <= 0;

m_axis_s2mm_cmd_tdata <= 0;

end

else if(sync_trigger) begin

m_axis_s2mm_cmd_tvalid <= 1'b1;

m_axis_s2mm_cmd_tdata <= {9'd0,32'h1000_0000,1'b0,1'b1,6'd0,1'b1,23'd8192};

end else if(m_axis_s2mm_cmd_tready) begin

m_axis_s2mm_cmd_tvalid <= 0;

m_axis_s2mm_cmd_tdata <= 0;

end

end

endmodule在ILA中验证,AXI总线已经反馈OKAY,并且STS也是回报OK的.

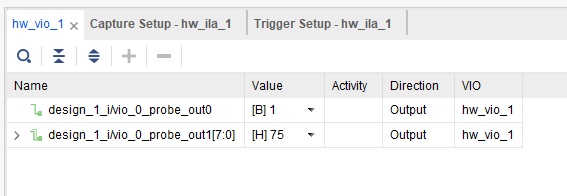

我的VIO配置.

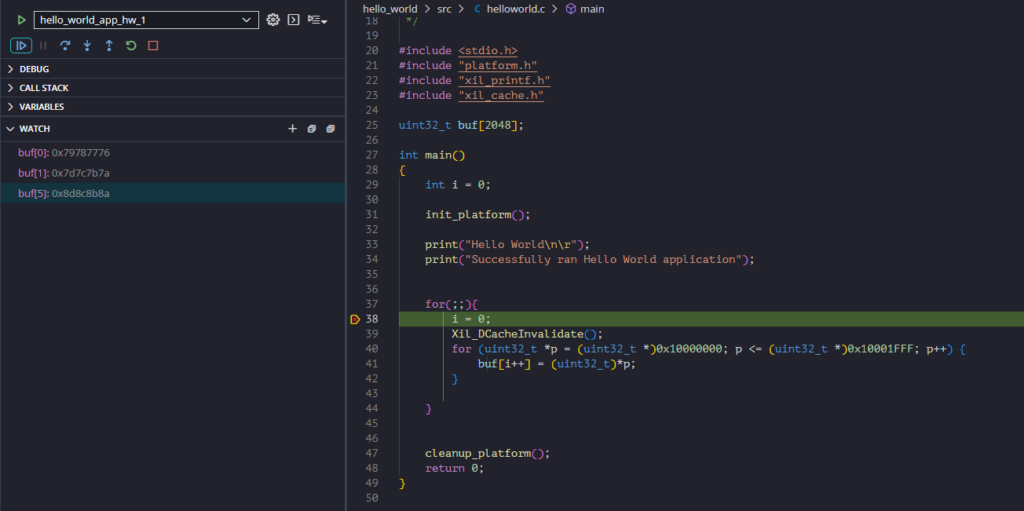

PS读取偷懒的话,就失能全部Cache验证.

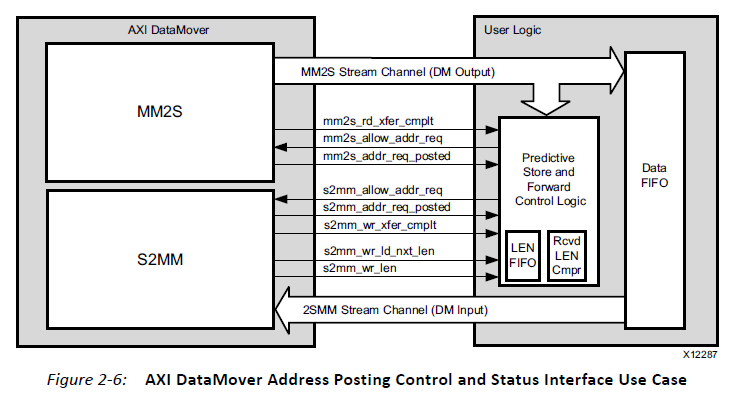

另外也可以使用Store and Forward功能,这样就算输入输出不同宽度,也是可以暂存,但是他只在Full模式有效,不如多使用几个额外IP.